The Advantages of Transitioning into Flexible Packaging

Competitive pricing, increased sales, improved performance, sustainable and eco-conscious options, and ease throughout the supply chain ― these are just some of the benefits of transitioning into a flexible packaging program.

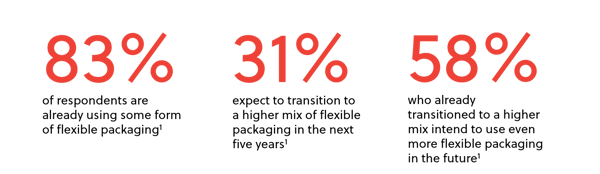

According to Flexible Packaging Transition Advantages - Consumer Study, transitions into flexible packaging cited operational benefits and an increased ability to meet consumer needs1:

- 49% of respondents cited production cost as a reason for the shift to flexible packaging;

- 45% cited shipping/transportation efficiencies as a reason for the shift;

- 45% cited convenience as a benefit that influenced them to transition;

- 39% cited fitting consumer lifestyle trends as a benefit;

- 57% of respondents were able to lower production costs in some way after transitioning to use of flexible packaging;

- 55% reported a sales improvement after increasing their use of flexible packaging

A critical task of packaging is to perform functionally as well as environmentally.

1. Flexible Packaging Takes Up Less Space

Floor space is critical to operations and the more space you have, the better. Flexible packaging reduces the amount of space on the floor and in transit; this means that in one truckload, you are receiving more product. Ultimately, flexible packaging releases lower carbon emissions in total due to its lightweight nature.

This is also important to retailers when mapping out shelf space to display your product. If your product is compact, convenient, and pops off the shelves, you could negotiate shelf placement by highlighting “eye level is buy level” or placing your product near complimentary items and brands.

This is also important to retailers when mapping out shelf space to display your product. If your product is compact, convenient, and pops off the shelves, you could negotiate shelf placement by highlighting “eye level is buy level” or placing your product near complimentary items and brands.

2. Convenience

The Flexible Packaging Transition Advantages - Brand Owner Study found that the flexible packaging segment has exhibited a projected compound annual growth rate of 4.7% by 20222.

With a conscious shift toward sustainable packaging, flexible packaging has offered a transition into mindful materials that help brand owners meet their goals. Due to this demand, manufacturers have been challenged to test new materials that boost sustainability profiles.

By testing these materials, producers are able to offer customers high shelf-life packaging with design appeal that caters to different commodities while remaining convenient.

Offering a flexible package in different pack-sizes caters to consumers feeding varying family sizes.

3. Less Waste

Production processes are engineered to avoid waste and to create a system that is mutually beneficial for the manufacturer and customer. Flexible packages, on average, use 60% less plastic and are 23% lighter when compared to rigid packaging3. These properties ultimately reduce production costs and reflect less waste in the package’s end life - even more so when the packaging does not end up in a landfill.

You’re also seeing a decrease in food waste as a result of flexible packaging’s enhanced barrier properties; this supports extended shelf life for fresh produce and food packed in flexible applications.

4. Recyclability

A previous downside of flexible packaging was its recyclability. As conversations regarding sustainability goals and corporate social responsibility have become focal, innovation on the material-side has evolved to include environmentally conscious materials that have been constructed to be compatible with store drop-off programs.

To learn more about the benefits of transitioning into a flexible packaging program, reach out to our Fox Packaging team; with over 50 years of packaging expertise, we will advise you as to the best direction for your commodity and brand according to your program goals.

Sources

1. https://www.flexpack.org/outreach-materials/flexible-packaging-transition-advantages-consumer-study

3.https://www.grandviewresearch.com/press-release/flexible-packaging-market

4. https://trayak.com/flexible-packaging-sustainable-future